MIG Welding Aluminum For Beginners

Aug 24, 2023

Welding aluminum can be a real head-scratcher, even for experienced welders. It's like trying to juggle flaming torches while riding a unicycle on a tightrope. Okay, maybe not that extreme, but you get the picture. Aluminum has a low melting point and a high thermal conductivity, which means it heats up and cools down faster than you can say "hot potato." This makes it tricky to maintain a stable arc and achieve a strong, clean weld. But fear not, brave beginner! With a little know-how and a lot of practice, you'll be welding aluminum like a pro in no time.

Why is Welding Aluminum So Difficult?

When welding aluminum, there are a few challenges that beginners may encounter:

- Aluminum has a higher thermal conductivity compared to other metals, which means it dissipates heat quickly. This requires precise control of the welding parameters to prevent overheating or burn-through.

- Aluminum forms an oxide layer on its surface, which can interfere with the welding process. Proper cleaning and preparation of the aluminum surface are crucial to achieve a successful weld.

- Aluminum has a lower melting point compared to other metals, making it more prone to distortion and warping during the welding process. Proper joint design and clamping techniques can help minimize these issues.

Tips for MIG Welding Aluminum

Here are some tips to help beginners achieve successful MIG welds on aluminum:

- Choose the right equipment: Use a MIG welder specifically designed for aluminum welding. It should have a spool gun or a push-pull system to feed the aluminum wire smoothly.

- Prepare the surface: Thoroughly clean the aluminum surface to remove any dirt, oil, or oxide layer. Use a stainless steel brush or a dedicated aluminum cleaner for best results.

- Select the correct wire and shielding gas: Use aluminum-specific welding wire and a shielding gas mixture of argon and helium. This combination provides good arc stability and reduces the risk of porosity in the weld.

- Adjust the welding parameters: Set the appropriate wire feed speed, voltage, and travel speed for the thickness of the aluminum being welded. Experimentation and practice are key to finding the optimal settings.

- Use proper welding technique: Maintain a consistent travel speed and angle to ensure even heat distribution. Push the weld puddle rather than pulling it to prevent contamination and improve penetration.

- Consider preheating and post-weld heat treatment: Preheating the aluminum can help reduce the risk of cracking, while post-weld heat treatment can improve the strength and durability of the weld.

Preparing Your Equipment to MIG Weld Aluminum

Before you dive headfirst into the world of aluminum welding, you need to make sure your equipment is up to the task. First things first, you'll need a MIG welder with a MIG gun. And don't forget to clean your aluminum thoroughly with a stainless steel brush to remove any dirt, oil, or alien goo that might interfere with your weld.

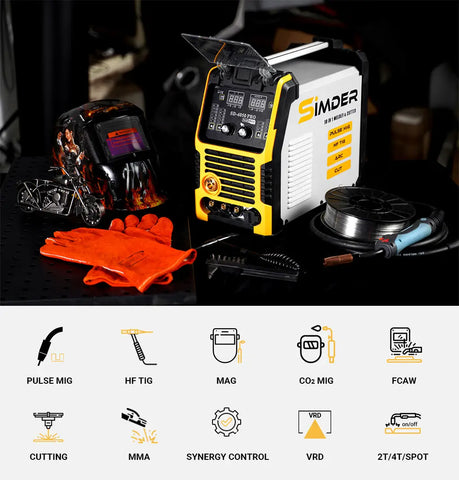

Some welders like the SSimder SD-4050 Pro 10 in 1 welder&cutter. Which will provide good results for hobbyist aluminum MIG welding needs.

MIG Welding Aluminum Wire Selection

Aluminum welding filler wire selection depends on base aluminum alloy and the conditions the finished part will be subjected to. Therefore, it's essential to match the filler wire with these two variables.

The most commonly used MIG aluminum welding wires are ER4043 and ER5356.

ER4043 is a general-purpose MIG welding wire used to weld 2014, 3003, 3004, 4043, 5052, 6061, 6062, and 6063 aluminum alloys. The welds provide high ductility and excellent resistance to cracking. Plus, the wire has silicon additions which lower the melting temperature and promote weld pool liquidity.

SSimder Silicon Aluminum Welding Wire ER4043 .035"

Conclusion

MIG welding aluminum is an excellent skill for beginners to learn. With the right techniques and safety precautions, you can create strong and reliable welds on aluminum materials. Remember to practice regularly and seek guidance from experienced welders to improve your skills. Happy welding!

Frequently Asked Questions

Is MIG welding aluminum easy?

Welding aluminum is more difficult than welding steel, but you are much more likely to create quality welds if you learn the basics. MIG welding aluminum is easier than TIG welding aluminum, and it requires less costly equipment. However, there are still many variables and areas where you can make a mistake.

Can I MIG weld aluminum without gas?

Yes, it is possible to weld aluminum with a MIG welder without gas. This is known as gasless MIG welding.

Is welding aluminum AC or DC?

Welding aluminum is ideal for alternating current (AC) TIG welding since the alternating current has positive and negative cycles. The positive cycle has a scrubbing effect on the metal surface by removing oxides that adversely impact weld quality.

What size MIG wire to use for aluminum?

When it comes to MIG welding, there are only two real choices-4043 or 5356 filler wire. They can be used to weld the following alloys: 3000, 4000, 5000 and 6000 series aluminum.