Why does the spool gun matter in welding?

Dec 16, 2023

Have you ever encountered the frustration of a welding gun refusing to feed wire or witnessed a tangled mess of welding wire disrupting your work?

If so, you're not alone. When tackling certain welding tasks, especially those involving soft metals like aluminum, traditional welding guns often face a myriad of challenges. Unlike harder metals like steel, aluminum demands a more precise and delicate approach to welding.

In conventional MIG (Metal Inert Gas) welding, the distance between the welding gun and the wire spool can lead to issues such as aluminum wire looping and knotting, significantly impacting the welding outcome.

So, is there a tool that addresses these challenges, improves welding efficiency, and ensures the quality of the weld?

The answer lies in the spool gun, a specialized tool designed for MIG welding. What sets it apart is its unique approach to wire control. The spool gun comes equipped with a small spool of wire mounted directly on the welding gun, effectively reducing the distance the wire travels from the spool to the weld joint. This design minimizes the chances of wire knotting and tangling, crucially enhancing the reliability of welding, especially when working with soft metals like aluminum.

Here are some key reasons why spool guns are important:

- Preventing Wire Tangling: Aluminum wire is softer and more prone to tangling than steel wire. Spool guns are equipped with a small spool of wire on the gun itself, which reduces the distance the wire travels from the spool to the weld puddle. This design minimizes the chances of wire tangling, ensuring a smooth and continuous welding process.

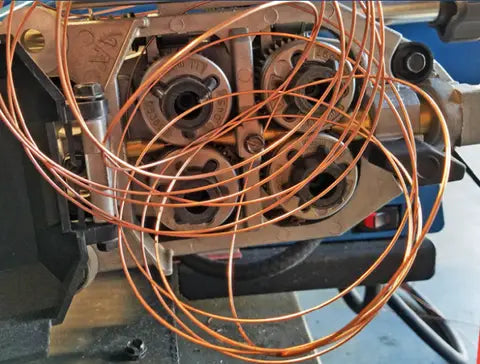

Source:americantorchtip.com/blog/top-5-causes-of-bird-nesting-and-how-to-fix-them/

- Reducing Bird's Nest Formation: Bird's nests occur when the welding wire becomes entangled and creates a mess of loops that can disrupt the welding process. Spool guns, by keeping the wire feed path short and controlled, significantly reduce the likelihood of bird's nest formation, improving the overall efficiency of the welding operation.

Source:https://weld1.weebly.com/blog/birdsnest

-

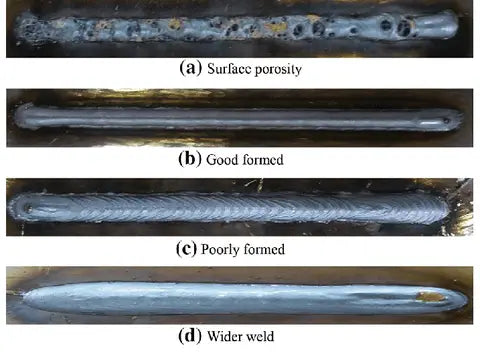

Improved Weld Quality: The precise control over wire feeding provided by spool guns contributes to better weld quality. This is particularly important when welding aluminum, as the softer metal requires more precise control to achieve clean and strong welds.

Source:https://www.researchgate.net/figure/Four-types-of-weld-quality_fig1_349045182

-

Enhanced Maneuverability: Spool guns are often lighter and more compact compared to traditional MIG welding guns. This makes them easier to handle and maneuver, especially in tight spaces or when working in positions where a longer welding gun would be cumbersome.

-

Minimizing Wire Contamination: Aluminum is more susceptible to contamination from moisture and other environmental factors. By keeping the wire in a sealed spool on the gun until it reaches the welding point, spool guns help minimize the risk of contamination, ensuring a cleaner weld.

-

Compatibility with Soft Metals: Spool guns are specifically designed for welding softer metals like aluminum, which have different welding characteristics than steel. They are equipped with the necessary features to accommodate the unique properties of these metals, allowing for successful welding without sacrificing quality.

In summary, the importance of a spool gun lies in its ability to address the challenges associated with welding soft metals, particularly aluminum. The design of the spool gun helps ensure smooth wire feeding, reduces the risk of wire tangling and bird's nests, and ultimately contributes to improved weld quality and efficiency.

Frequently Asked Questions

What is an aluminum spool gun?

What's a Spool Gun? A spool gun is a pistol grip style gun with a compartment for a wire spool roll to be attached directly onto the gun. The gun also comes with its own drive rollers inside the gun, so the wire can feed from the spool, through the gun and out into the weld.

Is aluminum spool gun AC or DC?

While AC (alternating current) is required for TIG welding of aluminium, this is NOT the case for MIG. Virtually all common MIG welding machines operate on DC (direct current) only, whether used for welding steel or aluminium.

Do aluminum spool guns use gas?

Pure argon gas is required to MIG weld aluminum — not an argon and CO2 mixture commonly used for welding steel.